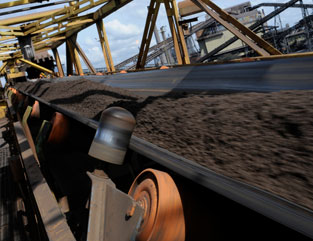

Flexsteel cable belts are world renowned for their consistent quality and unrivalled durability.

These cables, made of numerous metallic filaments, are designed to ensure great flexibility and allow effective and highly resistant splicing. The galvanized zinc plating acts as a bonding agent between cable and insulating rubber which creates a strong barrier against corrosion.

Continental and Rematech jointly provide technical support for belt selection according to transported materials and operating conditions.

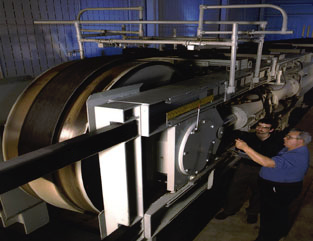

Continental offers an innovative continuous inspection system for Flexsteel cables coupled with a rip protection system. Do not hesitate to contact us for more information.